Since 2011, our company has been offering processing services for various materials, in accordance with the client's drawings and models. Today, our production line is equipped with the most modern equipment, which allows us to process various materials quickly, with high quality and inexpensively.

Since our company offers services for welding metals using the TIG and MIG methods, at the end of these works, the question of high-quality cleaning of products arises. One of the types of seam treatment after welding on non-ferrous metals is the ELECROCHEMICAL method of pickling and passivation. This procedure implies exposure to the heat-affected area using an electric current and specially designed electrolytes for cleaning, etching, passivation and polishing. When removing tarnishing colors from steel seams, we do not in any way spoil the surface of the metal itself, which means that if you use "mirror" (polished) steel, then after processing you will not see matte, dull spots in the heat-affected zone, which can remain when using nitrogen-containing pickling pastes. Likewise, nothing happens with a matte and polished surface. At the same time, after processing the steel using this technology, the alloying (passive) layer is completely restored, which protects the steel surface from corrosion during further operation.

CLEANING WITH CHEMISTRY

If the shape of the part does not allow mechanical cleaning, then one of the methods is chemical cleaning, during which the part is cleaned with very toxic chemicals. This method of cleaning is quite old and familiar, so many people continue to use it by inertia.

For cleaning with chemistry, it is necessary to strictly follow the processing technology, since even minor deviations from the procedure can cause the loss of the protective metal layer, which will cause rust in the future. The chemical elements used in this method are very toxic and require special care in handling, especially with regard to environmental protection. Therefore, processing a part by this method significantly increases the cost of the part, which is a serious factor if it is planned to be sold at retail.

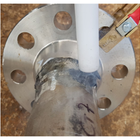

ELECROCHEMICAL CLEANING

This is a fairly new cleaning method that has not yet taken root in Latvia. The new technology is easy to apply, convenient and fast, which is why we are proud to offer our clients this opportunity.

This procedure involves exposure to the suture area with an electric current and specially developed electrolytes to clean the suture site. When removing by welding the left colors from steel seams, we do not in any way damage the surface of the metal itself. This means that if you use "mirror" (polished) steel, then after processing you will not see dull, dull stains in the area around the seam area, which may remain when using nitrogen-containing pickling pastes (see "cleaning with chemistry").

Likewise, nothing happens with a matte and polished surface. At the same time, after processing steel using this technology, the protective layer is completely restored, which protects the steel surface from corrosion during further operation. Therefore, if the appearance and quality of the part is important, and you also need to find the most convenient, fast and cheap solution for cleaning, we definitely recommend turning to the latest technology - electrolysis cleaning.

For more information and a specific price offer, please contact our managers in the contacts section.