Since 2011, our company has been offering processing services for various materials, in accordance with the client's drawings and models. Today, our production line is equipped with the most modern equipment, which allows us to process various materials quickly, with high quality and inexpensively.

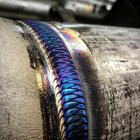

We perform TIG welding on a regular basis. TIG welding can weld: steel, aluminum, copper, titanium and two dissimilar metals. This process is ideal for welding hard-to-reach seams, S-seams, corners. TIG welding allows you to make very thin and high-quality seams, especially where it is important that the seam is invisible. Since we control the entire welding process with a welding torch, we can make cosmetic seams, automotive seams, and weld thin metals with a thickness of 0.1 mm.

The client can prepare a drawing on his own or contact our specialists in the design section. Our specialists quickly and efficiently, are able to remove dimensions from an existing sample or implement the wishes of the customer. After that the drawing / model becomes the property of the customer.

For more information and a specific price offer, please contact our managers in the contacts section.

During this type of welding, clean, strong and reliable seams are obtained, which often do not even need to be cleaned, since there is simply no slag on them. Therefore, TIG welding is not replaceable when working with stainless steel, aluminum and light alloys. A very high temperature is created in the tip of the welding machine - up to 1500 degrees. No additional substance is used here, everything is achieved using a high melting point. The weld material under the influence of heat begins to melt like ice cream and sticks both parts of the part together.

The advantages of TIG welding in the absence of metal spatter, a beautiful weld seam and the ability to weld thin products.